History

While the basic technique has not changed much, there are many families who have perfected and modified the technique over generations to achieve unique finishes.

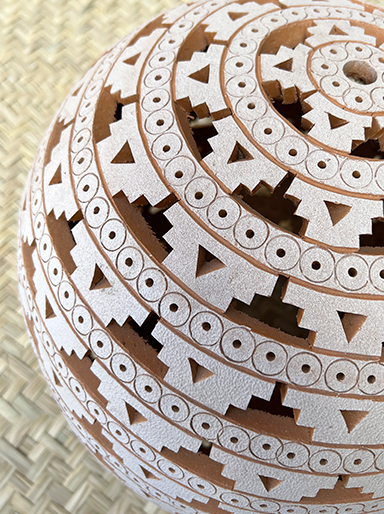

One such case is the Zarate family from Santa Maria Atzompa, Oaxaca. They have added a special step in the finishing process of the pottery. Prior to firing, they mix specific stones with water to cover certain parts of the piece. This mixture reacts to the heat of the kiln, resulting in a color and texture known as "barro blanco" or white clay.

Process

Collection

The artisans go to the hills to collect the red clay. They then clean it, removing branches and leaves, in order to mix it with water, which is necessary for kneading it to the required consistency.

Modeling

The artisans create by hand the base of the piece on the lathe, to gradually give it the desired shape.

Drying

The artisans create the base of the piece by hand on the pottery wheel, gradually shaping it with their hands to the desired form.

Finished

To achieve the white tonality, before firing, the piece is covered with a mixture of crushed stone soaked in water. This mixture is known as "barro blanco" or white clay.

Decoration

Using manual tools, they trace figures and symbols on the piece.

Baked:

The pieces are placed in a gas kiln, which reaches a temperature of over 1830°F.

As the pieces enter the high temperatures of the kiln, they undergo a transformation, shifting from a gray tone to a beautiful combination of orange on the interior and white on the exterior.